Our services

Azhineh Yadak was established in April 1997 as a limited liberty company with a specific focus on design and implementation of factory automation.

Engineering, Equipment and infrastructure of Automation

Perform engineering operations related to implementation, commissioning and maintenance: plastic injection, electronic hardware implementation, mechanical and hydro-mechanical installations, automation hardware and software, modern facilities and equipment for water treatment plants, recycling, pumping stations and the like.

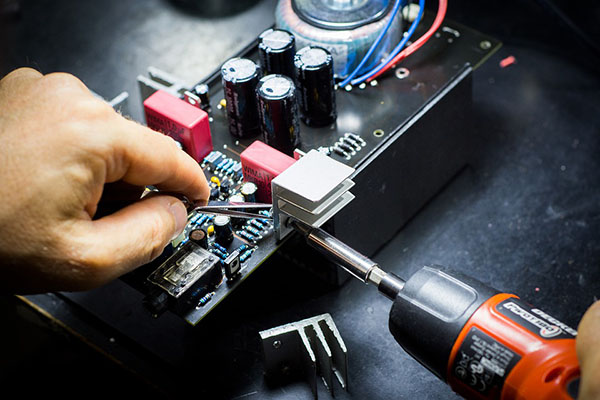

Design and Engineering of Power and Electrical

- Installation of low, medium and high voltage power lines, design, construction, installation and troubleshooting of industrial electrical boards, lighting and water pumping stations. Also design, consult, and draw all relevant maps.

- Manufacture and installation of support and installation of trays and ladders for cable, conduit, and duct

- Calibration of Instrumentation Devices and Control Valves

- Manufacture and installation of instrumentation holder base with associated canopies

- Installation of precision instruments

- Installation of control panels and equipment for control rooms

- Installation of analyzer, PLC and Vibration Monitoring devices

- Installing Junction Boxes and Local Boards

- Loop check system pre-boot operation

- Perform setup operations for precision instrument systems

- Installation of power and distribution transformers with corresponding duct bass

- Installation of high, medium and low-pressure panels

- Installation of earth connection system, cathode protection, lightning protection

- Installation of UPS, charger and associated batteries

- Installation of detector systems, fire alarm

- Perform all kinds of tests required for the above

- Electricity system startup operations

Industrial Technology Research

Providing comprehensive technology development plan, marketing, sales, consulting and recruitment, strategic planning for companies and public and private organizations, preparing technical, financial and support justifications, project control, and quality management.

- Investigating and recognizing the latest technologies in the automation industry

Solving problems in manufacturing processes using new technologies - Collaborate with external consultants on product lines to increase efficiency, reduce energy consumption and troubleshoot

- Upgrading the lines according to new technologies with the cooperation of technology companies

Industrial Molds

The increasing complexity and development of industrial molds has made the designs of 3D models a necessity for ease, precision, error reduction, and thus cost savings. For better visualization, it is necessary to create technical drawings of electronics in 3D. Three-dimensional execution will give the audience a better understanding of a topic or project of the highest quality and will increase the power of audience analysis, review, and decision making. The modeling steps in performing As-built mapping services include:

- Check equipment status and available maps

- Detailed 3D maps (Detail)

- Assemble mapping and mapping

- Final review of the model with the existing situation

- Determine the basic parameters of the scheme

- Perform plot calculations

- Examine standards related to the plan

- Harmonize design calculations with standards

- Provide detailed 3D maps (Detail) with related software

- Detail 3D assembly and model overlay

- Final analysis and model optimization

- Preparation of 2D model execution maps

Automobile Spare (plastic) Parts Design

Offering a complete solution for automobile plastic spare parts from analysis, to mold design, to injection automation, training and implementing hardware at various plants. Primarily focused on wiring, spark plugs and spark wires.

Renewable Energy Sectors

Given the increasing growth in the utilization of renewable energy sources and the benefits of using these energy sources in reducing environmental pollution as an alternative to fossil fuels, increasing energy security and larger-scale green investments to achieve economies of scale. With the aim of reducing environmental risks in various industries, we set up a new energy analysis unit and carried out extensive studies in collaboration with leading companies. The main activities of this unit include:

- Site Evaluation, Identification, and Forecasting of Renewable Energy Sources

- Presenting proposals for renewable energy sources

- Design and review of completed designs

- Environmental Impact Assessment and Risk Assessment

- Technical inspection services during construction of equipment used in power plants with renewable energy sources and operation inspection and monitoring

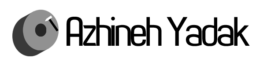

Hardware Reverse Engineering

Wide range of reverse engineering services including but not limited to:

Technical

- Documentation: Maps, equipment reviews, related parts, and installation location and operating conditions

- Manufacturing drawings: Drawing and drawing drawings from disjointed parts and equipment

- Providing, archiving and duplicating technical specifications for parts and equipment

Answering the employer’s technical questions about the material, shape or process of making the piece